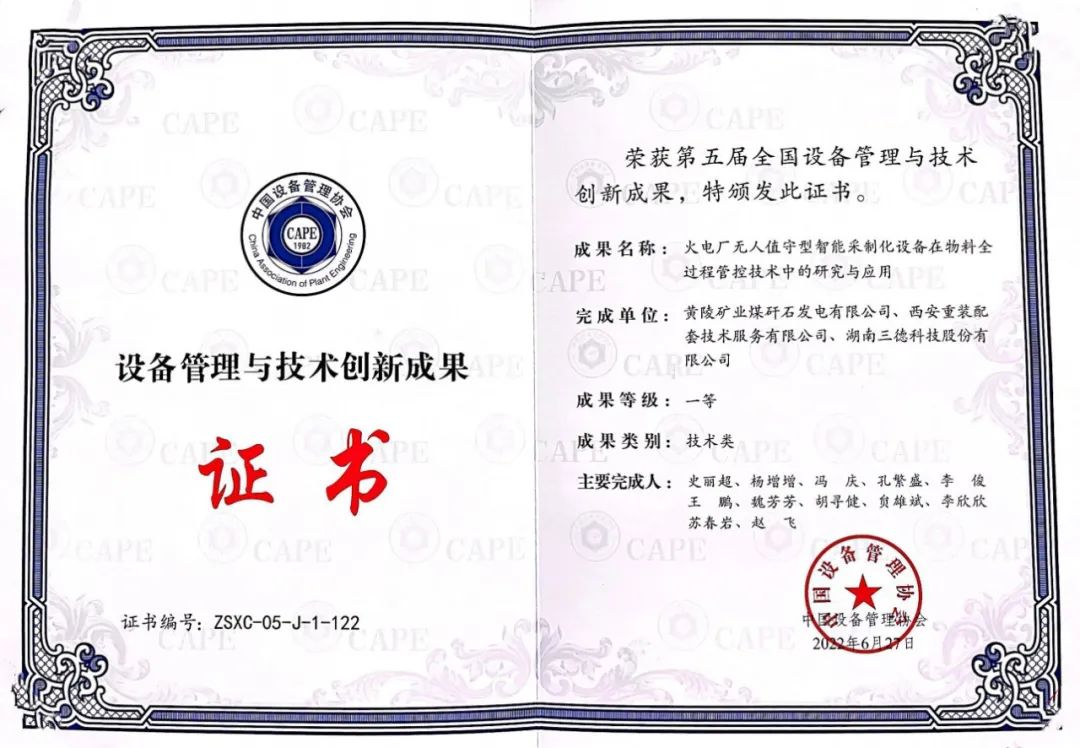

Sundy robotic sampling-sample preparation-analysis system helped Huangling Mining Industry Coal Gangue Power Generation Co., Ltd. win the first prize of national innovation achievement

Recently, “The Fifth National Equipment Management and Technology Innovation Achievement Exchange Conference” sponsored by the China Association of Plant Engineering was held in Wuhan. The “Research and Application of Unattended Intelligent Sampling-Sample Preparation-Analysis Equipment in Thermal Power Plants in the Whole-process Management and Control Technology of Materials” project led by Sundy’s user Huangling Mining Industry Coal Gangue Power Generation Co., Ltd. stood out from more than 1,700 projects across the country. Won the first prize of the 5th National Equipment Management and Technology Innovation Achievement.

“Research and Application of Unattended Intelligent Sampling-Sample Preparation-Analysis Equipment in Thermal Power Plants in the Whole-process Management and Control Technology of Materials” is based on the “Intelligent Material System” as the support, research the technological innovation achievements of the application. At the end of 2020, Sundy joined hands with Huangling Mining Industry Coal Gangue Power Generation Co., Ltd. to be responsible for the supply and implementation of the project’s products, including the SDRASC robotic sample storing and checking system, the SDRPS robotic sample preparation system, the SDIAS intelligent analysing system, and the SDPS All-pass sampling system and fuel management and control systems. This is the most robot-configured project in the fuel intelligent EPC project currently on the market (other projects generally only have a single robotic sample preparation system or robotic test system), and it is well deserved to win this honor with strong cooperation.

“Research and Application of Unattended Intelligent Sampling-Sample Preparation-Analysis Equipment in Thermal Power Plants in the Whole-process Management and Control Technology of Materials” is based on the “Intelligent Material System” as the support, research the technological innovation achievements of the application. At the end of 2020, Sundy joined hands with Huangling Mining Industry Coal Gangue Power Generation Co., Ltd. to be responsible for the supply and implementation of the project’s products, including the SDRASC robotic sample storing and checking system, the SDRPS robotic sample preparation system, the SDIAS intelligent analysing system, and the SDPS All-pass sampling system and fuel management and control systems. This is the most robot-configured project in the fuel intelligent EPC project currently on the market (other projects generally only have a single robotic sample preparation system or robotic test system), and it is well deserved to win this honor with strong cooperation.

Real shot of sampling area

Real shot of sample preparation, storage, pneumatic conveyor and analysing area

Real shot of SDRPS robotic sample preparation system

Real shot of SDRASC robotic sample storing and checking system

Real shot of SDIAS intelligent analysing system

At present, the “intelligent material system” has been successfully on duty in the 2×300MW units of Huangling Mining Industry Coal Gangue Power Generation Co., Ltd., realizing the intelligent and automatic management and control of the whole process of incoming coal inspection, sampling, sample preparation, storage and inspection, and testing, makes up for the shortcomings of coal-fired intelligent management and control, and truly replaces manual sample preparation and sample testing. While reducing the labor intensity of workers and improving labor productivity, it also reduces human factors in the process of coal sample analysis and meets the needs of both the supply and demand sides for scientific, fair, and quality-based pricing, realizes scientific and efficient management, and lays a solid foundation for the construction of smart power plants.