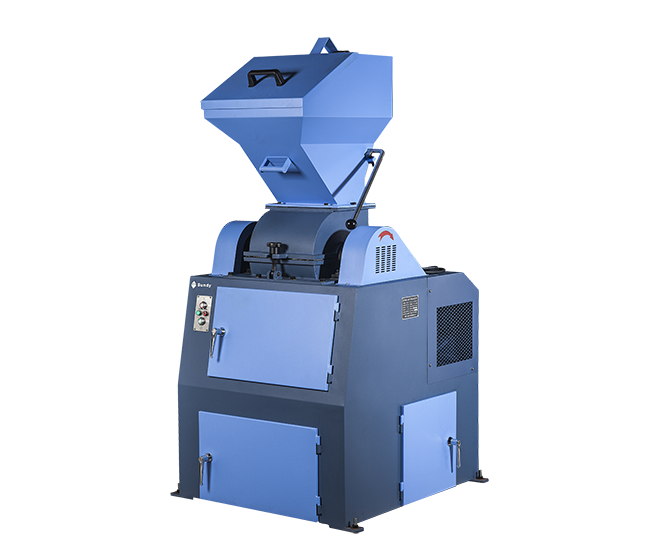

SDSPS All-pass integrated sampling and sample preparation system

It is widely used for automatic coal sampling, sample preparation and total moisture test in the fields of power, steel, coke, coal, chemical industry, cement, port, etc.work flow diagram

|

|

|---|

Product description

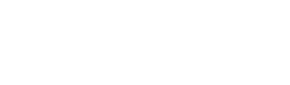

Diagram for all-pass integrated sampling and sample preparation system

Innovation points

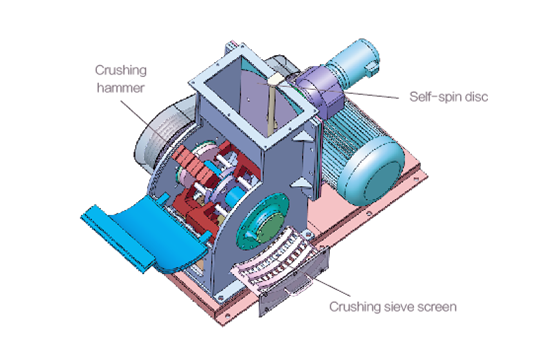

1. “Blockage” prevention

With the “Umbrella SpinsTM” technology, the coal sample could realize self-cleaning as the receiving disc self-spins and the cleaning pole self-cleans by scraping, making it not adhere and accumulate, so as to avoid “blockage”.

2.”Stuck” prevention

①The system could automatically sense and judge the material crushing and processing situation in the crushing cavity, and based on this control the feeding speed by frequency conversion to realize the linkage and matching with crushing capacity.

② The system adopted the hammer crushing structure with strong crushing capability and equiped the unique separate-slot type crushing sieve screen and hammer head , the efficiency of crushing and discharging is improved and “stuck” due to overfeeding beyond crusher ability is avoided, to minimize the sample residue.

3.Seamless connection of sampling and sample preparation

With Sundy unique moisture keeping and auto feeding sampling dividing/ collecting device, dividing (secondary dividing), transportation belt, after completion of single sample collection, the sample will be transported through automatic belt to automatic drying or secondary crushing for sample preparation, sampling and sample preparation system connection can be realized seamlessly.

4.High collection rate of automatic pulverization

The system adopted a high-speed material cutting technology for automatic pulverization, with self-dropping and

collectingTM technology, making the pulverization collection rate greater than 95%, sieving pass rate 100% (tested by the state coal center) and good sample representativeness.

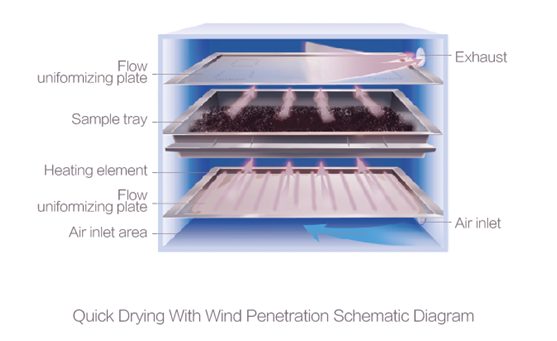

5.Automatic adhesion judging and pre-treatment

Before entering the intelligent sample preparation system or pulverizing step, the system can judge the level of coal adhesion to see if it is necessary to process drying pre-treatment. If necessary, the coal sample will be pre-treated through low temperature quick drying with wind penetration technology to avoid adhesion/blockage/ blending, ensure automatic sample preparation well- functioned and minimize the sample residue. The drying efficiency can be greatly improved with hot wind penetration to the coal layer and the increased contact surface, and the damage of sample physical properties from infrared light waves and other drying methods could be effectively avoided.

Main functions

①Identify the received coal resource and vehicle information by RFID technology to realize automatic allocation of sampling pots.

②Sampling solution is finalized automatically to reduce dead zone of sampling and avoid empty sampling and wrong sampling. Random sampling can be realized to increase sample representativeness.

③The whole sampling process is fully automatic. The speed of transporting subsample by belt is matched with the following ability of crushing procedure. Furthermore, unique crusher structure can avoid the traditional problems of “blockage” and “stuck”. Seamless connection of crushing, dividing and intelligent sampler preparation can prevent manual intervention.

④Finish the process of iron removing, sample transportation, sample weighing, crushing, dividing, drying, pulverizing, packing, discarding sample recycling, etc automatically. Output total moisture sample, backup sample and 0.2mm analysis sample according to customer requirement without adhesion, blockage and blending.

⑤Sample preparation procedure equips dust extraction module. Dust pollution can be decreased and sample preparation environment can be improved so that system life can be increased and operation comfort level can be higher.

⑥Optional total moisture test system to test total moisture online

Featured Products

Inquiry

Please feel free to submit your inquiry information to us. We will contact with you as soon as possible.