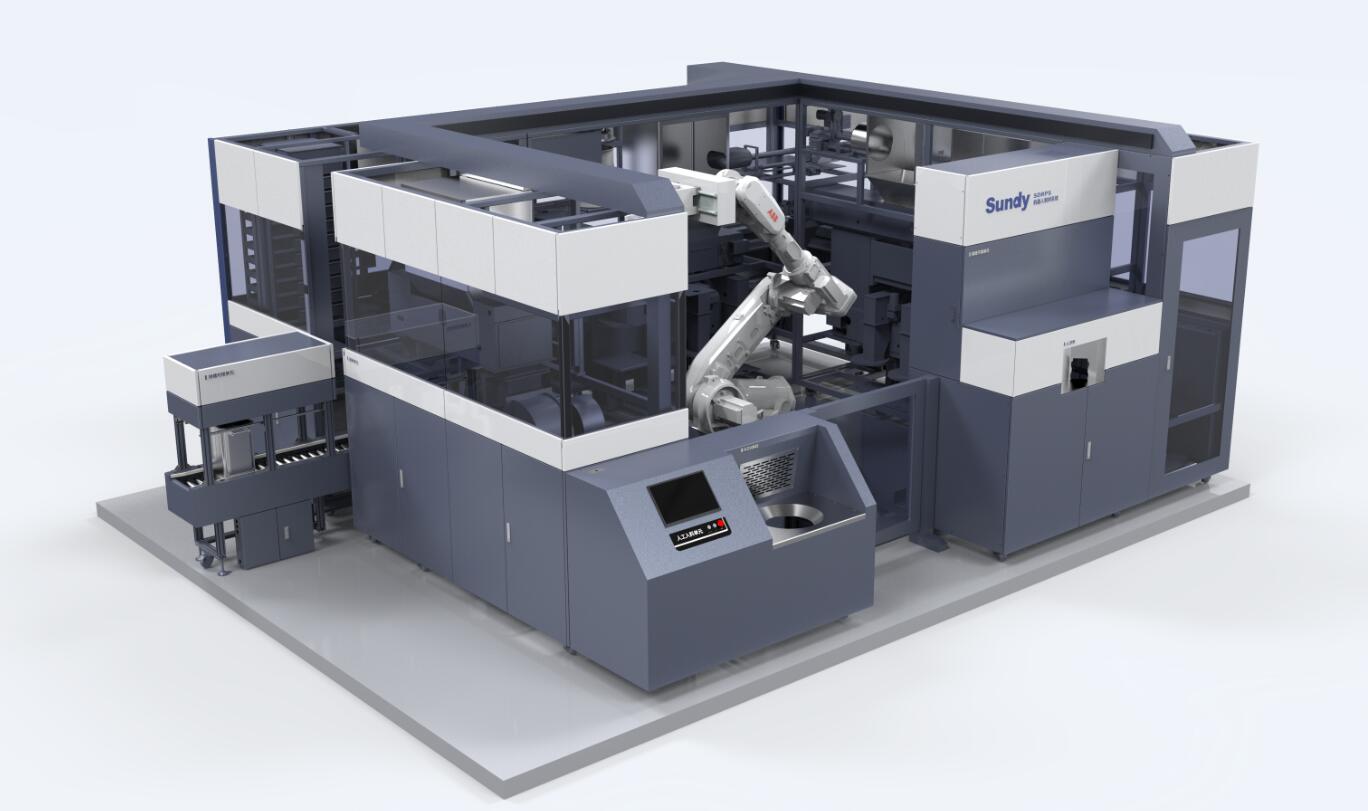

Product description

Application

It is mainly applicable to the automatic coal sample preparation in the field of electric power, coal industry, chemical industry, metallurgy, building materials,institutions, environmental industry, universities, etc. (online total moisture analysis system and pre-level drying system are optional).

Conformance to Standards

GB/T474 《Method for sample preparation of coal》

GB/T19494.2《Mechanized sampling of coal – part 2 Sample preparation of coal》

GB/T19494.3《Mechanized sampling of coal – part 3 Precision measurement and bias test》

GB/T12642《Performance and test methods for industrial robots》

Specification:

| Item | Specification | |

| Feeding Size | ≤100mm | |

| Feeding Sample Weight | 15-120kg | |

| Discharge Size/Weight/Quantity | Total Moisture Sample | 6mm or 4.75mm ;Weight≥1.25kg;1~2 Pieces |

| Back Up Sample | 3mm or 2.36mm;Weight≥700g;1~2 Pieces | |

| Analysis Sample | 0.2mm or 0.25mm or 0.212mm;Weight≥60g;1~3 Pieces | |

| Dividing Way | Belt Divider、Rotary Divider | |

| Dividing Tolerance | ≤10% | |

| Efficiency | Constant discharge sample interval:About 15min | |

| Sample preparation time for a single sample:About 50min | ||

| Drying Method | Quick drying with wind penetration at low temperature | |

| Robot Axis | 6 Axis | |

| Pulverized Sample Collection Rate | ≥98% | |

| Power Requirement | AC 380V 50Hz,65KW | |

| Dimension(L*W*H) | 6m×5m×2.8m | |

| Recommended Installation Requirement(L*W*H) | 7m×8m×3m | |

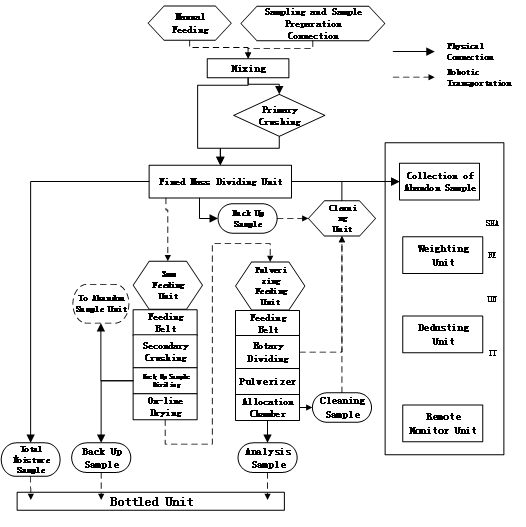

System flow diagram

Features

- The whole process is visible, the results are accurate, controllable, reliable, traceable and representative.

① the 6-axis robot is used to automatically complete the automatic transfer of samples and container cleaning, which can effectively avoid the cross contamination and leakage of materials in the transport link and ensure the reliability of sample results;;

② from feeding, crushing, dividing, pulverizing to packing, all links have weight monitoring, and the coal sample container can be cleaned in real time, relying on the whole link of sample weight monitoring technology, can provide the sample loss rate of each link, sample weight stability analysis;;

③ High collection rate: “percussive” automatic pulverizing method is adopted.The self-sink ™ technology was used to collect samples. The collection rate of the system powder was greater than 98%, and the sieving rate was 100%. The samples were representative;

④ The use of transparent glass shell design, the whole process of sample preparation can be observed, the process is more reliable.

- Coal/ Moisture adaptability,no obstacle.

① Global unique air-permeable low-temperature rapid drying technology and umbrella rotation technology ensure that the key links such as crushing and dividing, pulverizing are not restricted by coal and moisture, and the whole process of sample preparation is smooth without stick and block;

② For coal with high moisture or humidity, pre-stage drying system can be selected according to the needs.

- Unattended intelligent operation.

① The imported professional robot is used to complete such actions as cleaning and filling of sample transfer container, which reduces the number of moving mechanism of the system and greatly improves the stability of the system;

② One-key operation, the system automatically all through the operation, the whole process to eliminate human intervention;

③ crushing/dividing/lifting/pulverizing devices using durable components, long service life;

④ The industry’s first remote control and diagnosis system, real-time online monitoring system operation status and the status of each module, automatic warning, diagnosis, provide pre-maintenance, effectively reduce the failure rate of the system, improve the reliability.

⑤ With intelligent reminder function (test start/end reminder, fault reminder, directional push), can be unattended, timely inspection (need to connect the external network)

4.Modular design, sample preparation scheme flexible, wide range of application。

① modular design, the robot can adjust the sample preparation process according to different needs, sample preparation scheme is flexible, can maximize the use of different user needs. ;

② the robot peripheral equipment adopts modular design, convenient disassembly, maintenance;

③ The system covers a small area of only 56 square meters (including maintenance space, the actual area of 30 square meters) to meet the installation requirements, can be applied to more users on the site.

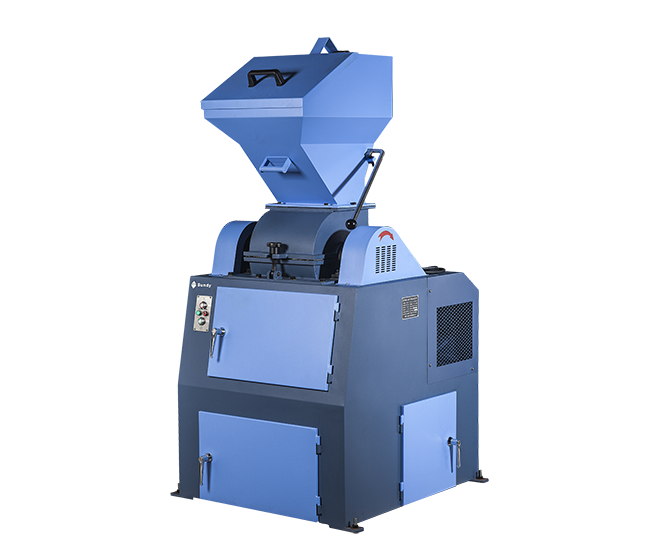

Featured Products

Inquiry

Please feel free to submit your inquiry information to us. We will contact with you as soon as possible.