Total Solution for Full-Process Fuel Management and Control

System adopted Sundy original patented technologies, which are crucial for the realization of the automation & integration of sampling and sample preparation and coal yard dynamic control

|

|

|---|

Product description

Trace to its source, fuel management has always been around “Quality” and “Quantity” two basic points. “Quality” management is mainly concerned with sampling, sample preparation, analysis etc. and “Quantity” management mainly relates to received coal measurement, coal yard management, etc.. Among them, the sampler, sample preparation and coal yard management are weak steps. After three generations’ development, the 4th generation solution featured of “Unmanned” .

Based on deep insight of user requirements and design idea and thinking of industrial 4.0, Sundy, started from the essence of fuel management, through Internet of things (Internet + advanced sensor) and successful application of the core patent technology, introduces the fourth generation solution of fuel management industry

System Features

①Whole process fuel management.

②With high automation, human intervention can be avoided and unmanned operation can be ensured.

③Intelligent management for information flow.

④With remote monitor, system operation status can be supervised, diagnosed and managed online.

⑤Modularized design.

Key Technologies

system adopted Sundy original patented technologies, which are crucial for the realization of the automation & integration of sampling and sample preparation and coal yard dynamic control, thus to make sure the real unmanned operation of the system in full process.

Advantages

①Unmanned operation for full process fuel management (except analysis test).

②Objective, authentic and reliable data.

③With pre-service mode, stable and reliable system running can be ensured.

Key System 1

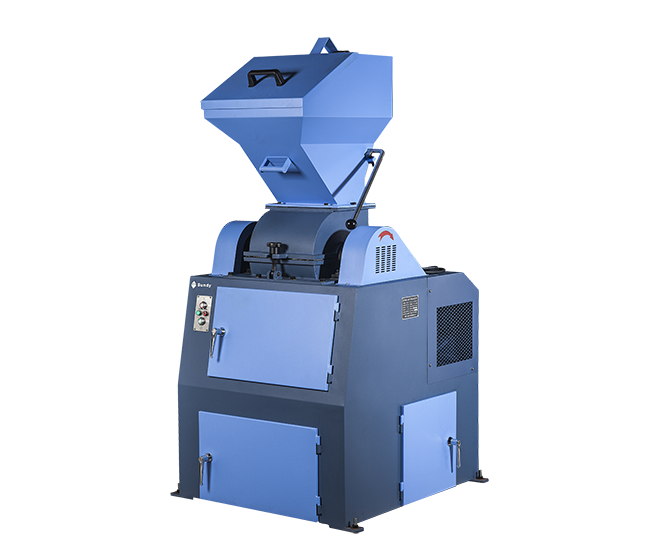

All-pass integrated sampling and sample preparation system

Seamless “Quality” control in all processesCurrently sampling and sample preparation are divided to two independent procedures for fuel quality management. It is difficult to manage it with high risk when transferring coal sample between the two procedures. Based on the launch of all- pass sampling system and all-pass sample preparation system, Sundy launched all-pass preceding stage sample preparation system successfully by technology innovation to resolve the problems of serious adhesion, blockage and poor sample preparation.

The system can realize the functions including automatic collecting primary sample, primary crushing for total moisture sample, backup sample and 0.2mm analysis sample and testing total moisture online. High automation, unmanned operation and integration can be realized to avoid manual intervention.

System composition

Key System 2

Coal-yard dynamic management & control system

Subverted innovation “Quantity” managementSundy brought in the concept of “warehouse management” to manage coal-yard. Traditional way is to measure coal weight indirectly by “volume×density”. This dynamic system is to install a certain quantity of sensors at the bottom of coal yard to form the sensitive weight platform. End user can know the information including coal position, coal type, coal quality, coal quantity and weight so that digital warehouse management for coal can be realized and manual way can be stopped.

Key System 3

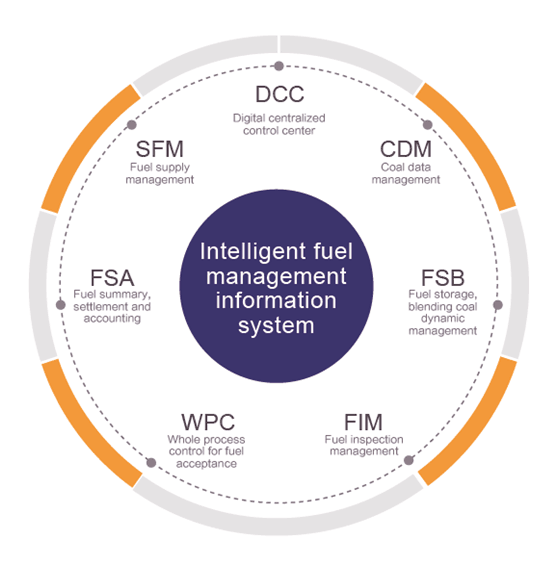

Intelligent fuel management information system

Intelligent control for whole process with wide coverage, no human interventionThe system can realize the functions such as general purview management, coal data collecting and management, coal blending management, digital centralized control center, inspection monitor, coding, supply management, settlement, etc. It can improve the fuel management efficiency and support the strategic decision making. Furthermore, the functions of contract management and supplier evaluation can be realized including the modules of monitor video, sampling/sample preparation/analysis data, trend prediction, planned contract, expense management (budget, cost, settlement, etc) and supplier management.

System software structure

Key System 4

Remote service system

Reliable and innovated method

①On-line system monitoring & self-diagnosis

②Preventative service before failure occurs.

Remote service is the guarantee for the normal operation of system. Through the application of Internet of things technology (advanced sensor + Internet), it could effectively shorten the response time, reduce the failure rate, possible management risk and time and efficiency loss, and improve the quality and reliability of system running by realizing remote management, diagnosis and service.

The subsystem has the following three core functions

Remote management

Capable of “file” management of system products, including basic information, maintenance/upgrade records, status data, etc. Remote system suspension after failure to minimize the failure affection to the lowest.

Remote diagnosis

Online monitoring to each subsystem, key components and wearing parts, and remote transmission to the client and supplier side for remote diagnosis and data collection of equipment or key parts operation status and precision.

Remote control

Based on the data of on-line monitoring and diagnosis, guidance for operation and maintenance and efficient arrangement for service can be realized.

Auxiliary Module 1: As received coal measurement and management

With new modern technology like internet of things and RFID, based on a series of facilities, summarizing the related information of as received coal, vehicle, equipment and people to realize efficient management for fuel dispatch, entering, sampling and supervision of discharge, collected data and information can be transferred to the following application procedures.

Auxiliary Module 1: As received coal measurement and management

With new modern technology like internet of things and RFID, based on a series of facilities, summarizing the related information of as received coal, vehicle, equipment and people to realize efficient management for fuel dispatch, entering, sampling and supervision of discharge, collected data and information can be transferred to the following application procedures.

Auxiliary Module 2: Sample management

Sample coding

Every sample will be given an exclusive identify code after being sealed by sample preparation system. Encryption management can be processed to prevent manual intervention.

Intelligent sample storing & checking management

Adopting SDASC100 automatic sample storing & checking system, supporting storing and taking sample automatically or manually. The system can be used independently or connected to sample preparation system and sample transmission system. It changed the traditional coal sample management mode to be efficient mode with the functions of authentication, sample recognition, expiration alert and security alarm.

Automatic sample transmission

According to actual situation at customer site, adopting vertical elevator and horizontal device or pneumatic transmission way to transfer the samples among sample preparation system, automatic sample storing & checking system and standard lab.

Auxiliary Module 3: Intelligent video access control

Equipped with intelligent video access control system at key procedure of fuel management. Working process can be real-time and human intervention can be reduced.

Featured Products

Inquiry

Please feel free to submit your inquiry information to us. We will contact with you as soon as possible.