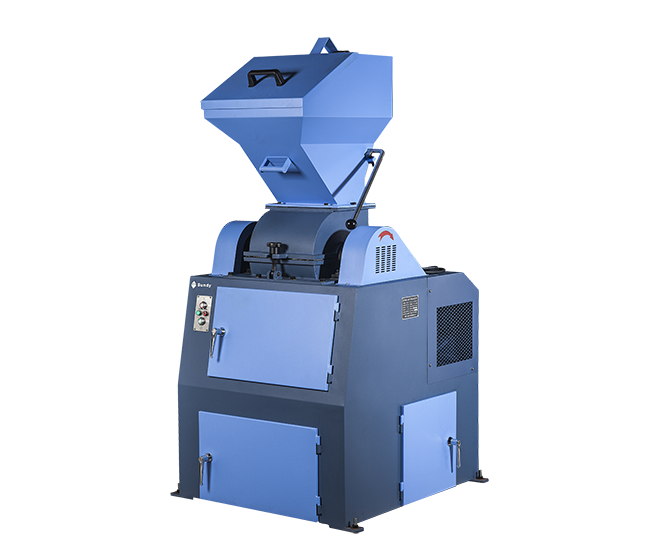

Product description

Traditonal jaw crusher need to adjust minimum jaw plate interval by visual check, its disadvantages are as follows:

①Big deviation, screening experiment is needed to check if the interval is good or not.

②Jaw plate collision due to small interval, service life is affected.

③Dynamic adjustment and self-protection functions, visual display of plate interval, interval can be adjusted during operation.

④Crushing size can be controlled without screening test.

⑤Avoiding the collision of jaw plate, extend the service life.

⑥Jaw plate is made of high-chromium or high-manganese steel (optional).

⑦No fixing is needed. The instrument can be placed on a cement floor due to the rubber bottom and foot.

⑧With unique sliencer, noise below 85 dB.

Specification:

|

Description |

SDJC100*60a |

|

Feed Size(mm) |

≤50 |

|

Discharge Size (mm) |

3-13(adjustable) |

|

Productivity(kg/h) |

45-550 |

|

Power Requirement(V) |

AC 380V |

|

Max Power(kW) |

1.5 |

|

Weight(kg) |

200 |

|

Dimension(mm) |

940*640*730 |

|

Speed of Eccentric Shaft(r/min) |

466 |

|

Moisture(Total Moisture) |

≤12% |

|

Description |

SDJC150*125a |

|

Feed Size(mm) |

≤100 |

|

Discharge Size (mm) |

6-38(adjustable) |

|

Productivity(kg/h) |

1000-2000 |

|

Power Requirement(V) |

AC 380V |

|

Max Power(kW) |

4 |

|

Weight(kg) |

420 |

|

Dimension(mm) |

1245*700*1010 |

|

Speed of Eccentric Shaft(r/min) |

466 |

|

Moisture(Total Moisture) |

≤12% |

Featured Products

Inquiry

Please feel free to submit your inquiry information to us. We will contact with you as soon as possible.