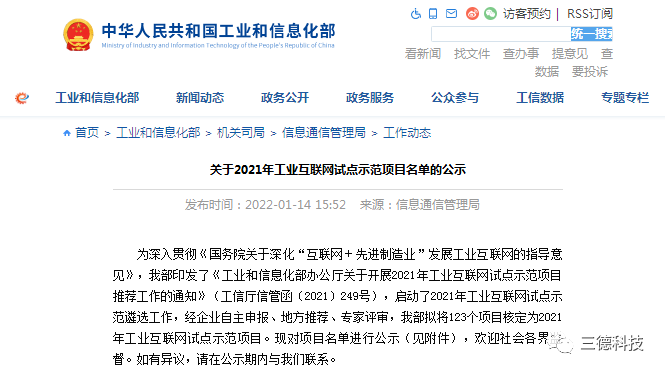

Sundy’s Project was selected into the National Industrial Internet Pilot Demonstration List

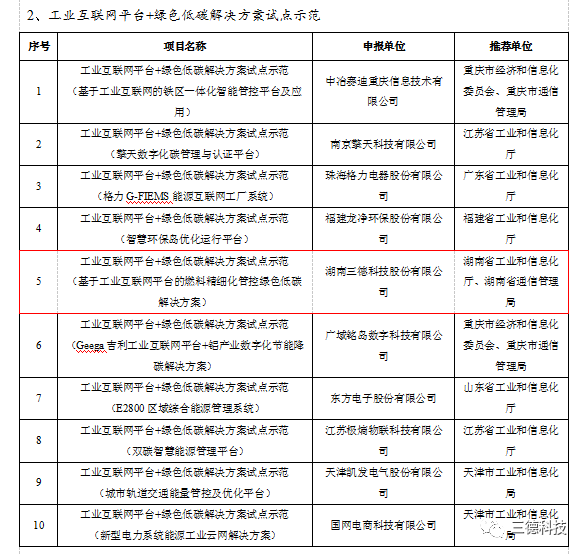

Recently, The Ministry of Industry and Information Technology released the “List of Industrial Internet Pilot Demonstration Projects in 2021”, and Sundy’s “Green and Low-Carbon Solutions for Fuel Refinement Control Based on Industrial Internet Platform” was successfully listed and selected for platform integration Innovation direction – Industrial Internet Platform + Green and Low-Carbon Solutions Pilot Demonstration, becoming one of only 10 enterprises in China! This is another honor that Sundy has won in the direction of industrial Internet after being awarded the Ministry of Industry and Information Technology ‘s Industrial Internet Innovation and Development Project – Industrial Internet Smart Energy Network Application Solution Provider.

Industrial Internet Platform + Green and Low-Carbon Solutions Pilot Demonstration List

The selection of industrial Internet pilot demonstrations is organized by the Ministry of Industry and Information Technology of the People’s Republic of China to select benchmarks for industrial Internet integration application projects across the country, focusing on 17 specific directions in four categories: network integration innovation, platform integration innovation, security integration innovation and park inheritance innovation. Aims to explore and promote more new models, new formats and new scenarios, and give full play to the important role of the Industrial Internet in quality improvement, efficiency enhancement, cost reduction, greenness, and safety. The selected projects represent the latest model and the highest level of national industrial Internet integration applications.

Sundy’s “Green and Low-Carbon Solutions for Fuel Refinement Control Based on Industrial Internet Platform” focuses on the business links of fuel quality acceptance, inventory management, procurement planning and settlement involved in the whole life cycle of energy from entry to furnace and open up the energy data chain. Through the automation, networking, informatization, visualization and centralized management and control of equipment and data, ensure the authenticity and accuracy of fuel quality and quantity data, and ensure fair and just transactions; improve energy management level and utilization efficiency; help enterprises to achieve intelligent energy monitoring, dynamic allocation, Energy saving, emission reduction and low carbon management. The solution is widely used in thermal power, metallurgy, chemical, coal and other high-energy-consuming enterprises, a total of more than 200 new/renovated projects have been implemented, which have achieved remarkable results in cost reduction and efficiency enhancement, comprehensive energy conservation, etc., effectively promoting the green, low-carbon and sustainable transformation and development of high-energy-consuming enterprises.

Implementation Case of Sundy Fuel Digital Intelligent Control Center

In the future, based on platform construction, Sundy will continue to strengthen the development of cross-platform systems to expand the scope of application of the solution, improve the effect of energy saving and emission reduction, and promote more enterprises to effectively use the advanced technological achievements of the industrial Internet, thereby contributing to green and high-quality development, really play an exemplary role in the industry’s benchmarking and demonstration!