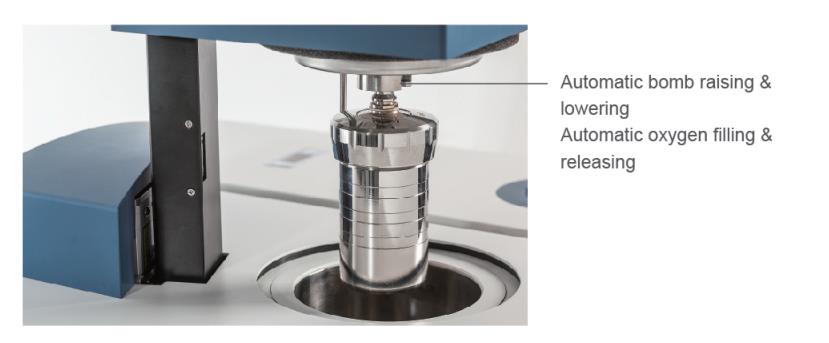

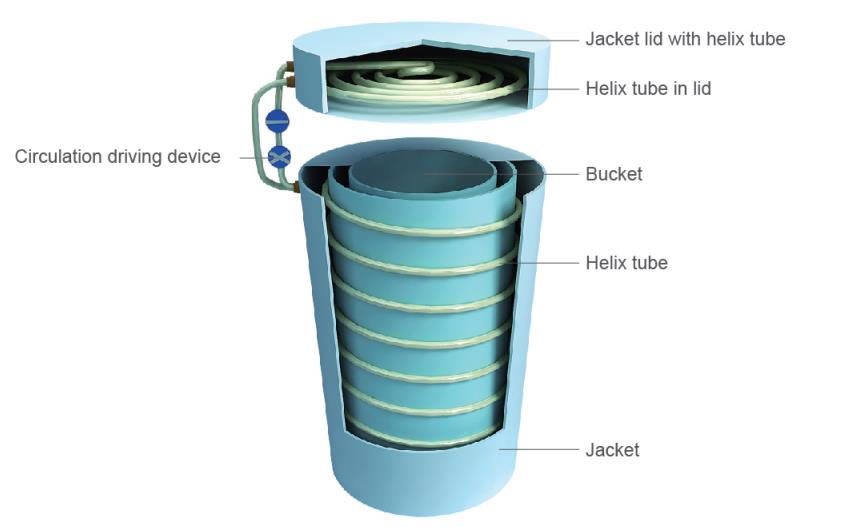

Highlights Optimized design, automatic oxygen filling & releasing, automatic bomb raising & lowering. 1、Unique bucket water circle system, which is able to determine water volume for each testing automatically. New stainless steel oxygen bomb can be easily assembled and disassembled. High stirring efficiency by propeller, faster heat transfer of oxygen bomb, testing time is greatly reduced. 2、Unique automatic press type oxygen filling & releasing design, no blockage, much more stable than traditional automatic calorimeter. 3、Equipped with a semiconductorthermostaticwater tank with cooling and heating More precise temperature control and lower power consumption and noise than conventional compressor cooling water tank. 4、High automation: bomb raising & lowering, oxygen filling & releasing, oxygen filling pressure and air tightness detection, bucket water volume constant, bucket water temperature control, pipeline flushing, water change, etc. Accurate and reliable test result 1、Larger heat capacity, it makes the testing result more accurate and reliable. 2、Support two ignition methods: nickel wire and cotton thread. Reasonable structure, reliable operation, safe and environment friendly. 1、With self-diagnostic function, malfunction can be detected accurately, easy to maintain. 2、Unique crucible support design, convenient to use. Good environment adaptability, precise, accurate and reliable rest result. 1、Helix tube multi-point isothermal technology, create a controllable and stable internal environment (consists of jacket and jacket lid, temperature difference<0.05℃), stop the interference of external environment (such as air flow, temperature) to bucket, test result is reliable. 2、Independent jacket and bucket water system. After the test, bucket water automatically flow back into water tank, no affection between inlet and outlet of bucket water and jacket water. Jacket water temperature is stabilized. Specification:

Description SDAC1200 Analysis Time Fast mode <10min,Standard mode<12min Precision mode <14min (Default) Temperature Resolution 0.0001K Precision(RSD) (based on analysis of 1g Benzoic Acid) ≤0.05% Heat Capacity Stability ≤0.2% within 12 months System Structure Benchtop Conformance with Standard ISO 1928, ISO 9831,ISO18125,ASTM D5865, ASTM D240, ASTM D4809, ASTM E711, ASTM D5468,GB/T 213,GB/T 30727, AS 1038.5,BS EN 15400, BIS1350 Precision(RSD) ≤0.08% Bomb volume 250ml Calorimeter Type Isoperibol Oxygen Filling Fully automatic oxygen filling & releasing, fully automatic bomb raising & lowering Bomb Washing Manual Max. Bomb pressure 20Mp Bomb Identity Yes Gas Requirement 99.5% Oxygen Water Requirement Distilled Water Energy Measurement Range 0~50000J Bucket Filling Automatic Constant Volumetric Tank with Temp Control Device Bucket determine water volume automatically Independent Bucket and Jacket Water System Yes Stirring Method Propeller Power Inverter No Ambient Temperature 10-35°C Average Temperature Increase 2℃ Temperature Measurement PT1000 Working Temperatures 35℃ Cooling method Refrigerating Device Network Yes Power AC 220V (-10% +10%)50/60Hz Max.Power 0.6KW Dimension Main body: 428*565*485 Water tank: 220*565*410 Weight 50kg Advance Calculation Yes Analysis Report Yes Statistics Report Yes System Monitor Yes

0086-731-88112150 sales@sandegroup.com

0086-731-88112150 sales@sandegroup.com

0086 731 88112150

0086 731 88112150 0086 731 88134650

0086 731 88134650 sales@sandegroup.com

sales@sandegroup.com